SE-3F1-55-7-ATP-035, TubeTrace with HPT thermon

Item #: SE-3F1-55-7-ATP-035

PRODUCT INFO

Thermon

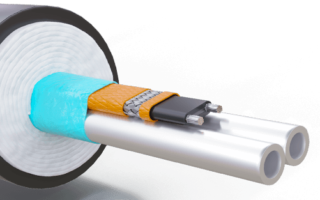

TubeTrace Type SE Electrically Heated Instrument Tubing with HPT Power-Limiting Heat Tracing, 3/8″ Process Tube O.D., 316 SS Seamless Process Tube Material, HPT 15 w/ft. 240 Vac Heat Trace Type, OJ/Fluoropolymer Heat Trace Option, ATP Bundle Jacket, 0.035″ Process Tube Wall Thickness TubeTrace, with “cut-to-length” HPT power-limiting heat tracing, is designed to provide freeze protection or temperature maintenance from 40°F (5°C) to 350°F (177°C) for tubing where high temperature exposure capability is possible. HPT withstands temperature exposures of 500°F (260°C). The composite construction of the heating element and fiber substrate, plus an additional fiber cushion layer, make HPT an exceptionally durable heating cable. Durability has made TubeTrace with HPT the industry standard for high temperature emissions and process analyzer applications. Power-Limiting HPT heat tracing: • Varies in response to the surrounding conditions along the entire length of a circuit. • Lower risk of overheating the tube or product than with constant watt designs. • HPT is approved for use in ordinary (non-classified) areas and hazardous (classified) areas. Certifications/Approvals: • FM Approvals • Ordinary Locations • Hazardous (Classified) Locations o Class I, Division 2, Groups B, C and D o Class II, Division 2, Groups F and G³ o Class III, Divisions 1 and 2 • Underwriters Laboratories Inc. • Ordinary Locations • Hazardous (Classified) Locations o Class I, Division 2, Groups B, C and D o Class II, Division 2, Groups E, F and G³ o Class III, Divisions 1 and 2 o Class I, Zone 1, AExe ll o Class I, Zone 2, AExe ll • Canadian Standards Association • Ordinary Locations • Hazardous (Classified) Locations o Class I, Division 2, Groups A, B, C and D o Class II, Division 2, Groups E, F and G o Class I, Division 1, Groups A, B, C and D o Class II, Division 1, Groups E, F and G o Ex e II Note: 1. Black ATP is standard, other jacket materials are available. 2. This reflects maximum exposure for heater. If bundle jacket is to remain below 140°F (60°C) in +80°F (27°C) ambient (in consideration of personnel burn risk) tube temperature must remain below 400°F (205°C). Alternative designs to keep jacket below 140°F (60°C) in higher ambients and/or with higher tube temperatures are available. 3. CL. II, Div. 2 requires Thermon design review.