DÂY GIA NHIỆT THERMON USX

dây gia nhiệt , THERMON USX self-regulating heat tracing is specifically engineered for critical process maintenance and freeze protection applications where ultra-high temperature ratings are required. USX enables the use of ambient sensing controls for applications with continuous exposure temperatures up to 240°C (464°F). Constructed using Thermon’s unique and proven monolithic co-extrusion process, USX advances self-regulating heat tracing technology to the ultimate frontiers of performance and reliability.

The heat output of USX heat tracing varies in response to the surrounding temperature. Variations in the ambient temperature or heat lost through the thermal insulation are compensated for automatically along the entire length of a heat-traced pipe.

FEATURES

- Higher continuous operating and exposure temperatures 240°C (464°F), creating new possibilities for reliable self-regulating technology

- Thermon’s unique and proven monolithic co-extrusion technology provides superior performance and reliability

- Enhanced safety and ease of installation for electric heat tracing systems for high temperature applications

APPLICATION

USX self-regulating heat tracing is specifically

engineered for critical process maintenance and

freeze protection applications where ultra high

temperature ratings are required. USX enables the

use of ambient sensing controls for applications

with continuous exposure temperatures up to

240°C (464°F). Constructed using Thermon’s unique

and proven monolithic co-extrusion process, USX

advances self-regulating heat tracing technology to

the ultimate frontiers of performance and reliability.

The heat output of USX heat tracing varies in

response to the surrounding temperature. Variations

in the ambient temperature or heat lost through

the thermal insulation are compensated for

automatically along the entire length of a heattraced pipe.

USX heat tracing is approved for use in ordinary

(nonclassified) areas and hazardous (classified) areas.

RATINGS

Available power densities …10, 20, 30, 39, 49, 66 W/m @

10°C

(3, 6, 9, 12, 15, 20 W/ft @ 50°F)

Supply voltages…………………………………110-120 or 208-277 Vac

Max. operating temperature

Continuous (power-on)…………………………….240°C (464°F)

Max. exposure temperature

Intermittent (power-on or off)……………….250°C (482°F)

Continuous (power-off)…………………………….240°C (464°F)

Minimum installation temperature …………..-60°C (-76°F)

Minimum bend radius

@ -15°C (5°F)…………………………………………………….10 mm (0.38”)

@ -60°C (-76°F)………………………………………………..32 mm (1.25”)

T-rating 1

………………………………………………………………………………………………..

3, 6, 9, 12, 15-2 ……………………………………………..T3 200°C (392°F)

15-1 and 20-1………………………………………………T2D 215°C (419°F)

20-2 …………………………………………………………….T2C 230°C (446°F)

Based on stabilized design 2 ……………………………….T3 to T6

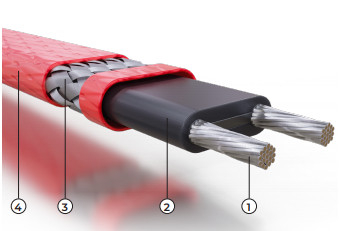

CONSTRUCTION

1 Nickel-plated copper bus wires (16 AWG)

2 Monolithic co-extruded semiconductive heating

matrix and fluoropolymer dielectric insulation

3 Nickel-plated copper braid

4 Fluoropolymer overjacket provides additional

protection where exposure to chemicals or

corrosives is expected.

Mail: Jan.tran@wili.com.vn